Insert Solid

Solid Hole/Shaft

Hole/Shaft Hole

Hole

The Hole command enables you to create simple and shaped hole in a solid.

The Hole selection list has the For screw check box which can be selected to create and redefine the standard, simple, and shaped holes.

In the Hole type: drop-down list the different hole type options are available as follows:

On snapping to any of these option from the drop-down list; the image of the respective hole type gets displayed, as shown in the image below.

You need to select the face of the solid for the Face selector and to position the center of the hole you are provided with the Type drop-down list.

Different termination types like Thru all, Blind, Up to face, From-to, etc of a hole feature are enlisted in the Extension drop-down list.

The standard thread forms enlisted in the Standards: drop-down list are as following:

All standard thread forms have different designation are available in the Designation drop-down list. By clearing the For screw check box you can customize the different parameters of the hole like its radius, depth etc.

The Hole type:: and Designation drop-down lists swaps their positions on selecting the Types by designation check box in the selection list. Also, the options displayed in the Hole type is depended on the selection made in the Designation drop-down list. There are multiple options under the More Options node:

When an assembly document is open, you are able to create a hole on a part of an assembly as per Assembly Feature concept. To do so, the Type drop-down list gets displayed in the Hole selection list. The following options are available in this drop-down list.

A warning message gets displayed in case a hole feature is intersecting the solid.

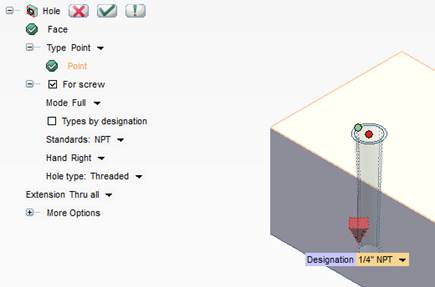

The new NPT features introduced in ThinkDesign are not cylindrical but tapered thread surfaces.

NPT Standard Hole

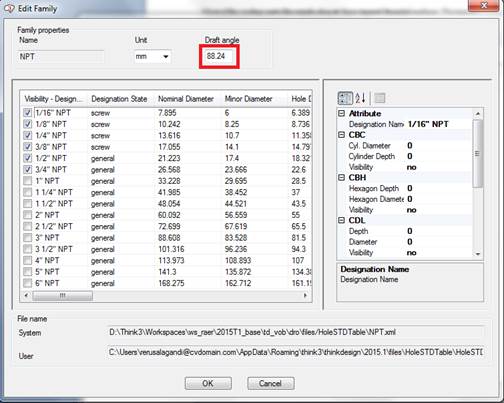

Draft angle is the amount of taper perpendicular to the parting line. This is an important parameter while creating the tapered holes, as it decides the slant and maximum depth of the hole.

According to NPT standard, the Draft angle for NPT Hole is 1.79. We need to set the same in Hole Standard Table as shown below.

Note: The value to be set for NPT Hole should be equal to 90 - Draft angle.

For a standard tapered hole, the larger diameter will always be equal to the value of Through/Nominal diameter shown in standard hole table. The smaller diameter is calculated based on the height of the hole and the draft angle.

NPT Standard threaded hole

The tapered surface for NPT standard thread hole will be similar to NPT standard hole. In case of NPT Threaded hole, the thread will be added to the tapered surface. The pitch of the thread will be as mentioned in the standards.

The larger diameter will always be equal to the value of Hole diameter shown in Hole Standard table. The smaller diameter is calculated based on the height and draft angle of the standard.

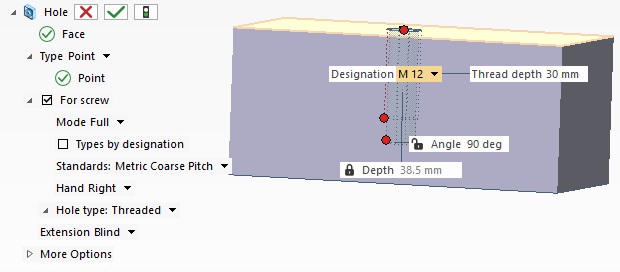

Flat Bottom Threaded Blind Hole

Threaded Blind Hole feature command having an option that allows to enable or disable the tip angle so that the feature will be created with flat bottom or without flat bottom.

When user launch's hole command and change hole type Threaded and Extension type "Blind" then "tip angle" mini dialog gets displayed in the graphical area of thinkdesign and this parameter has adjacent lock icon and can be read but not modified.

To change the status of lock icon, then user have to click the lock icon. This action turns the lock icon to an "unlocked" status. From now user will be enabled to change the value of this parameter.

Note: The value of tip angle should be between 1 and 90 degrees. By default the value is 60 degrees.

If value of tip angle is 90 then flat bottom has created for Threaded Blind Hole.